The Continental C90 engine is a renowned four-cylinder aircraft powerplant, widely used in small aircraft for its fuel efficiency and reliability. This parts manual provides essential details for maintenance, overhaul, and component identification, ensuring optimal engine performance and longevity.

Engine Model Designations

Continental C90 engines are designated as C90-8F and C90-8FJ, with dash numbers and letters indicating specific configurations. These designations reflect differences in horsepower, fuel systems, and other key engine specifications for various aircraft applications.

2.1. C90-8F and C90-8FJ Designations

The C90-8F and C90-8FJ are specific designations of the Continental C90 engine, indicating unique configurations. The “-8F” designation refers to a higher horsepower output, typically 95 HP, with a fixed-pitch propeller configuration. This model is often equipped with a Marvel-Schebler carburetor, optimized for efficient fuel delivery and performance in training and light aircraft applications.

The “C90-8FJ” designation denotes a similar engine but with slight modifications, including a different fuel system configuration. These designations are critical for identifying the correct parts and maintenance procedures, as outlined in the parts manual. The “-8” suffix indicates a specific series of the engine, while the “F” and “FJ” denote variations in fuel system components and performance characteristics. Understanding these designations is essential for proper engine maintenance, overhaul, and parts selection, ensuring compatibility and optimal performance. The parts manual provides detailed specifications for each designation, enabling users to accurately identify and procure the correct components for their specific engine model.

Structure of the Parts Manual

The Continental C90 parts manual is organized into clear, logical sections to facilitate easy navigation and identification of components. It begins with an introduction to the engine and its designations, followed by detailed illustrations and part numbers. The manual is divided into major categories, such as cylinders, bearings, and accessories, each containing subsystem-specific information.

Each section includes part numbers, descriptions, and visual references to ensure accurate identification. The manual also incorporates an illustrated parts catalog (IPC), which provides diagrams and exploded views of engine components. Appendices and indexes are included for quick lookup of specific parts or maintenance procedures. The structure is designed to support mechanics, maintenance facilities, and operators in performing routine maintenance, overhauls, and repairs efficiently. By following the manual’s organization, users can quickly locate the information they need, ensuring proper servicing and compliance with manufacturer standards.

Illustrated Parts Catalog (IPC)

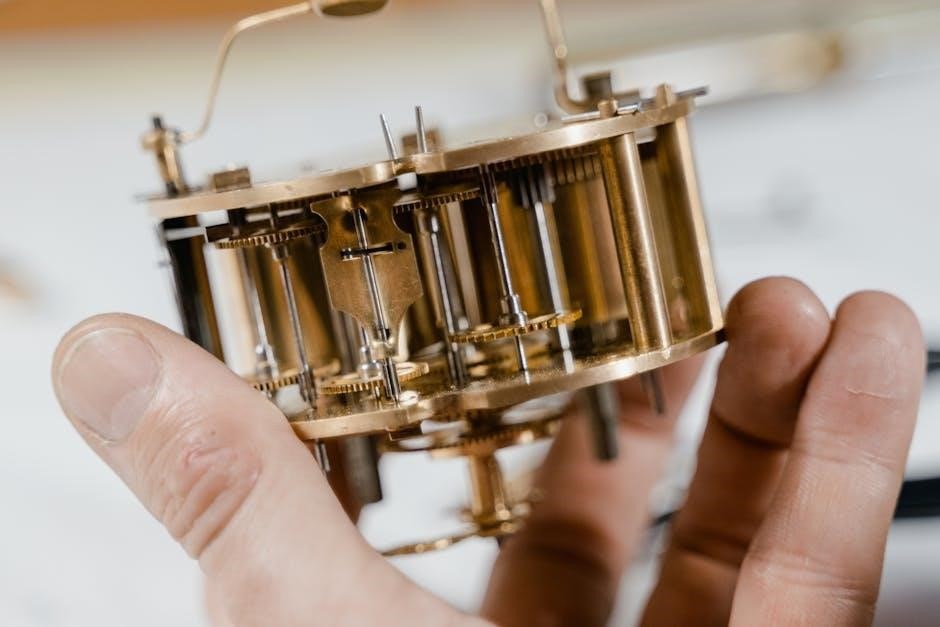

The Illustrated Parts Catalog (IPC) provides detailed diagrams and exploded views of engine components, listing part numbers and descriptions. It aids in visual identification and accurate ordering of Continental C90 engine parts for maintenance and repair.

4.1. Visual Identification of Parts

The Illustrated Parts Catalog (IPC) includes detailed diagrams and exploded views of the Continental C90 engine, enabling visual identification of components. Each diagram is accompanied by part numbers and descriptions, making it easier to locate and order the correct parts. The IPC is organized by engine section, such as cylinders, crankcases, and accessories, allowing users to focus on specific areas. Visual identification aids in verifying the condition and compatibility of parts, reducing errors during maintenance or overhaul. Users can cross-reference part numbers with the catalog to ensure accuracy. The IPC also highlights standard and optional components, helping users understand configuration variations. This visual approach simplifies the identification process, especially for complex assemblies like bearings and fuel systems. By providing a clear and comprehensive reference, the IPC supports efficient and accurate parts identification, ensuring proper engine maintenance and performance.

How to Use the Parts Manual

The Continental C90 parts manual is designed to guide users through the identification, ordering, and installation of engine components. To use the manual effectively, start by reviewing the table of contents to locate the relevant sections. The manual is divided into categories such as cylinders, bearings, and accessories, making it easier to navigate. Use the Illustrated Parts Catalog (IPC) to visually identify parts and cross-reference them with part numbers. When searching for a specific component, refer to the index or the detailed diagrams provided. Always verify part compatibility by comparing serial numbers and engine specifications. For ordering, ensure to use the exact part numbers listed in the catalog to avoid mismatches. The manual also includes update sections, so check for the latest revisions or bulletins. If unsure about a part or procedure, contact an authorized Continental Motors parts distributor for clarification. Regular updates and cross-referencing ensure accurate and efficient use of the manual for maintenance and overhaul tasks.

Cylinders and Parts

The Continental C90 engine features a robust four-cylinder design, with specific part numbers for cylinders, such as B3762 for A-series and A50222 for C-series. Engines with serial numbers 085: 31212 and higher, and C90: 42774 and higher, have shot-peened cylinders for enhanced durability and performance.

6.1. Cylinder Series and Upgrades

The Continental C90 engine features a range of cylinder series designed to enhance performance and durability. The A-series and C-series cylinders are identified by specific part numbers, such as B3762 for A-series and A50222 for C-series. Engines with serial numbers 085: 31212 and higher, and C90: 42774 and higher, are equipped with shot-peened cylinders, which improve strength and resistance to wear. Upgrades to cylinders often involve replacing worn or damaged components with genuine Continental parts to ensure compatibility and optimal performance. The parts manual provides detailed specifications for cylinder replacements, including torque settings and installation procedures. Users are advised to refer to the illustrated parts catalog (IPC) for visual identification of cylinder components and associated hardware. Regular inspection and maintenance of cylinders are critical to preventing engine damage and ensuring reliable operation. For specific upgrade requirements, consult the latest revision of the parts manual or contact an authorized Continental Motors parts distributor for guidance.

Accessories and Components

The Continental C90 engine utilizes a variety of essential accessories and components, including carburetors, fuel systems, bearings, and seals, which are detailed in the parts manual for proper maintenance and replacement procedures. Ensure all parts are genuine Continental for optimal performance and longevity.

7.1. Carburetors and Fuel Systems

The Continental C90 engine is equipped with a Marvel-Schebler carburetor, specifically designed to deliver precise fuel-air mixture for optimal engine performance. The carburetor is a critical component, requiring regular maintenance to ensure proper function. The parts manual provides detailed instructions for carburetor overhaul, including disassembly, inspection, and reassembly procedures. Additionally, the fuel system components, such as fuel pumps, lines, and filters, are essential for reliable engine operation. Proper installation and inspection of these parts are emphasized to prevent fuel leaks and ensure consistent engine power. The manual also highlights the importance of using genuine Continental Motors parts to maintain the integrity and performance of the carburetor and fuel system. Regular servicing and adherence to specified tolerances are crucial for maintaining fuel efficiency and engine reliability. By following the guidelines outlined in the manual, operators can ensure the carburetor and fuel system operate at peak performance, minimizing the risk of engine malfunctions during flight.

7.2. Bearings and Seals

Bearings and seals are critical components in the Continental C90 engine, ensuring smooth operation and preventing wear on moving parts. The engine utilizes high-quality bearings designed to withstand the stresses of flight, with specific part numbers designated for main bearings, rod bearings, and camshaft bearings. The parts manual provides detailed specifications for bearing sets, including installation instructions and torque values to ensure proper fitment. Seals are equally important, as they prevent oil leaks and maintain the integrity of the engine’s lubrication system. The manual emphasizes the importance of inspecting seals during maintenance and replacing them if any signs of wear or damage are detected. Proper alignment and lubrication during installation are crucial to avoid premature failure. Genuine Continental Motors parts are recommended to ensure compatibility and performance. Regular inspection and adherence to specified maintenance intervals are essential for extending the service life of bearings and seals, ultimately contributing to the overall reliability of the C90 engine. By following the guidelines outlined in the manual, operators can maintain optimal engine performance and minimize downtime due to component failure.

Bearing Sets and Dowels

Bearing sets and dowels are essential components in the Continental C90 engine, playing a vital role in ensuring proper engine alignment and smooth operation. The parts manual provides detailed specifications for bearing sets, including part numbers like 61102-8-2 and higher, which are compatible with various engine models. Dowels are specifically installed in the front bearing boss to maintain accurate alignment of engine components. Proper installation of these parts is critical to prevent engine vibration and wear. The manual outlines precise torque values and alignment procedures to ensure correct fitment. Regular inspection of bearing sets and dowels during maintenance is recommended to identify any signs of wear or misalignment. Replacing these components with genuine Continental Motors parts is strongly advised to maintain engine performance and longevity. Adhering to the guidelines in the manual ensures that the engine operates efficiently, minimizing the risk of premature wear and downtime. By following the specified procedures, operators can uphold the reliability and durability of the C90 engine.

Troubleshooting and Maintenance

Troubleshooting and maintenance are critical for ensuring the Continental C90 engine operates at peak performance. The parts manual provides detailed diagnostic procedures to identify common issues, such as unusual vibrations, oil leaks, or reduced power output. Routine inspections of components like cylinders, carburetors, and bearings are emphasized to catch potential problems early. Maintenance schedules are outlined, including recommended intervals for part replacements and lubrication. Operators are advised to use genuine Continental Motors parts to ensure compatibility and reliability. The manual also offers guidance on interpreting error signs, such as abnormal engine noises or temperature fluctuations, and provides step-by-step repair procedures. Proper documentation of maintenance activities is stressed to maintain compliance with aviation standards. By adhering to the troubleshooting and maintenance protocols, operators can extend the engine’s lifespan, reduce downtime, and ensure safe, efficient flight operations. Regular upkeep is essential for maintaining the C90 engine’s reputation for durability and performance.

Service and Support

Continental Motors offers comprehensive service and support for the C90 engine, ensuring operators have access to resources for maintenance and repairs. Authorized distributors provide genuine Continental parts, guaranteeing compatibility and reliability. The Illustrated Parts Catalog (IPC) serves as a key reference for identifying and ordering components. Technical support is available to assist with troubleshooting and maintenance, while service manuals and bulletins offer detailed guidance. Operators can contact Continental Motors directly for inquiries or issues, ensuring prompt resolution. Regular updates and revisions to the parts manual are distributed to keep users informed of the latest specifications and improvements. Additionally, training programs and workshops are available for mechanics and operators to enhance their understanding of the C90 engine. Continental Motors’ commitment to service and support ensures the C90 engine remains a trusted choice for aircraft owners and operators worldwide.